iMachining - the Revolution in CNC Machining

Put the knowledge and experience of hundreds of CAM and CNC masters in the palm of your hand, as the iMachining Wizard and Tool Path take you to an entirely new level of CNC performance!

Patented iMachining: "Truly Amazing"

This is what customers, machine tool manufacturers and tooling companies alike say about iMachining. The revolutionary iMachining CAM module, fully integrated in SOLIDWORKS, will make you and your CNC machines more profitable and more competitive than ever before.

iMachining is a real breakthrough in CNC milling tool path technology that enables extremely faster and deeper machining by optimizing tool cutting angles and feed rates throughout the tool path.

The Revolution in CNC Machining

- Increased productivity due to shorter cycles times - 70% savings and more!

- Dramatically increased tool life

- Unmatched hard material machining

- Outstanding small tool performance

- 4-axis and Mill-Turn iMachining

- Automatic, optimal feeds and speeds

- High programming productivity

- Shortest learning curve in the Industry

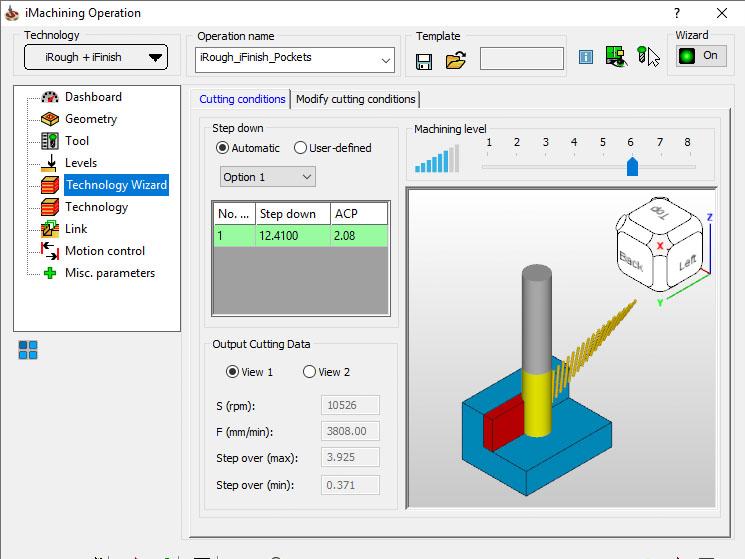

iMachining's Unique & Patented Technology Wizard

SolidCAM’s iMachining has the exclusive patented iMachining Technology Wizard, the industry’s first and only Wizard that automatically calculates optimal sets of Cutting conditions for the iMachining tool path.

The Wizard provides synchronized values of feed rate, spindle speed, axial depth of cut, cutting angles and chip thickness based on the mechanical properties of the workpiece and tool, while also keeping within the machine limits.

The "Machining level slider" lets the user choose from 8 selectable levels to automatically adjust for “real-world” fixture, tool holding and machine conditions. The "Machining level slider" makes it easy to overcome standard problems with spindle rigidity, fixture rigidity and cutting tool stability.

All SolidCAM customers worldwide, who bought iMachining, are enjoying immense savings and have gained a real competitive advantage.

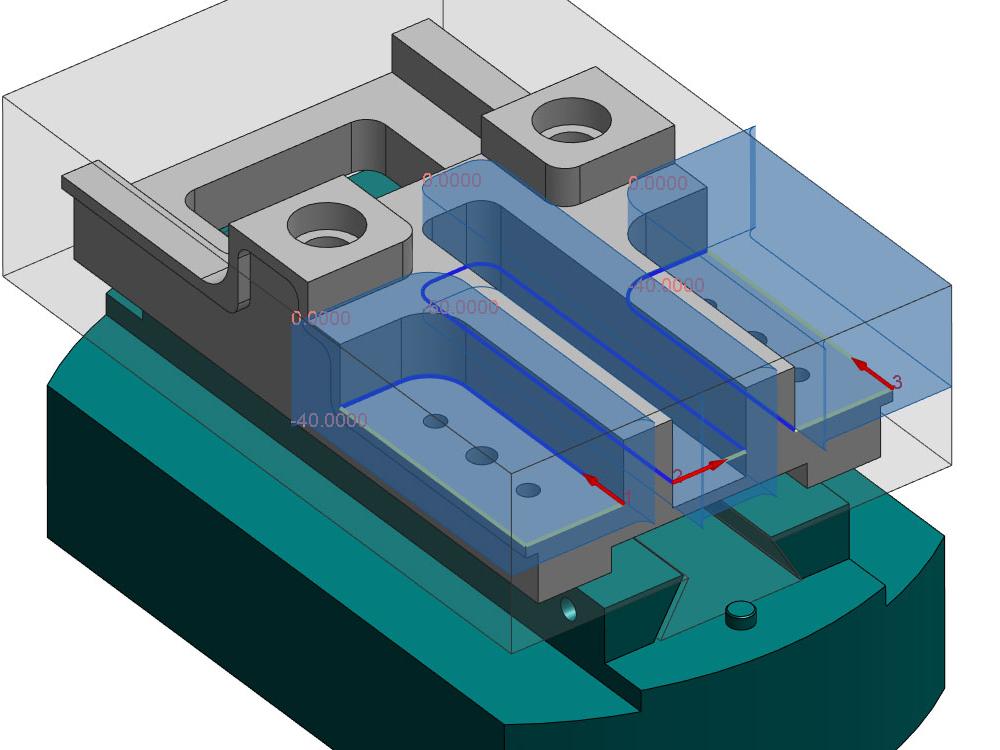

iRough, iRest, iFinish and Multi-tool Technologies

- Combined roughing, finishing and rest material functionality in one single job.

- Multi-tool: Easily define and edit related jobs that use multiple tools, all from within a single interface. Geometry and Levels are synchronized and rest material is tracked automatically.

- iRough + iFinish: Optimized roughing and finishing in the same job with the same tool. Ideal for prototyping and the machining of soft materials.

- iFinish: Suitable for hard materials and precise machining with separate tool for finishing floors and walls.

- Optimized rest roughing and bottom finishing of 2.5D features with various strategies.

- Automatic recognition and removal of rest material remaining through the drill tip.

Distinctive & Proprietary iMachining Tool Paths!

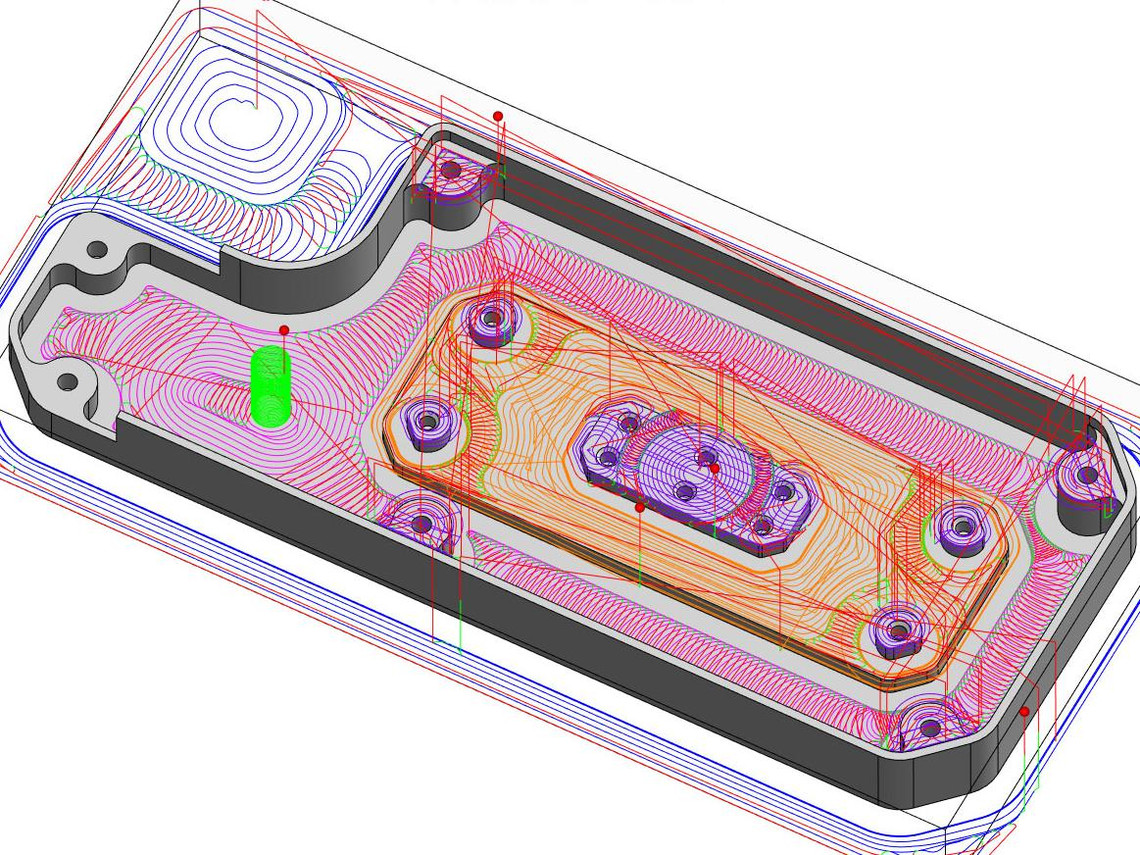

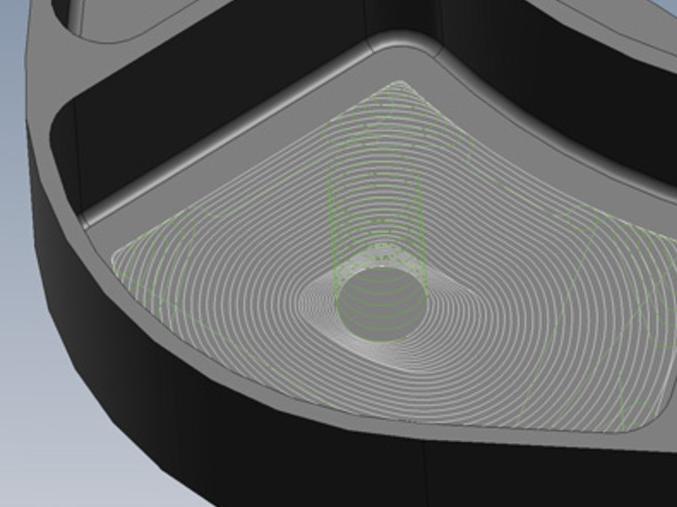

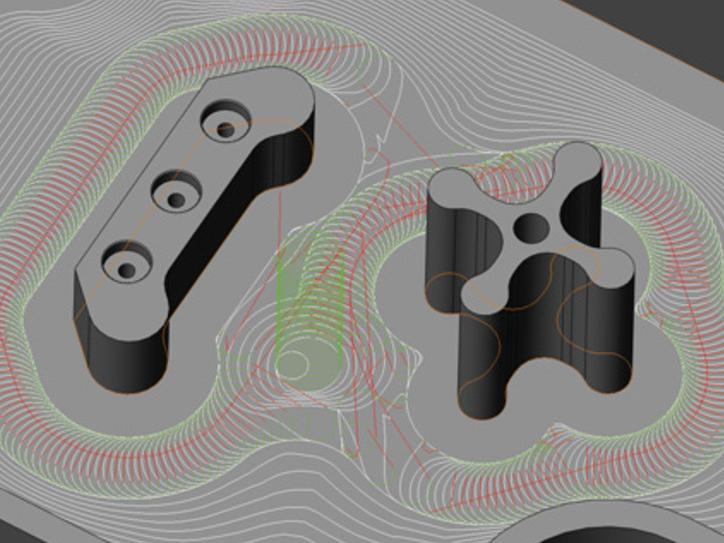

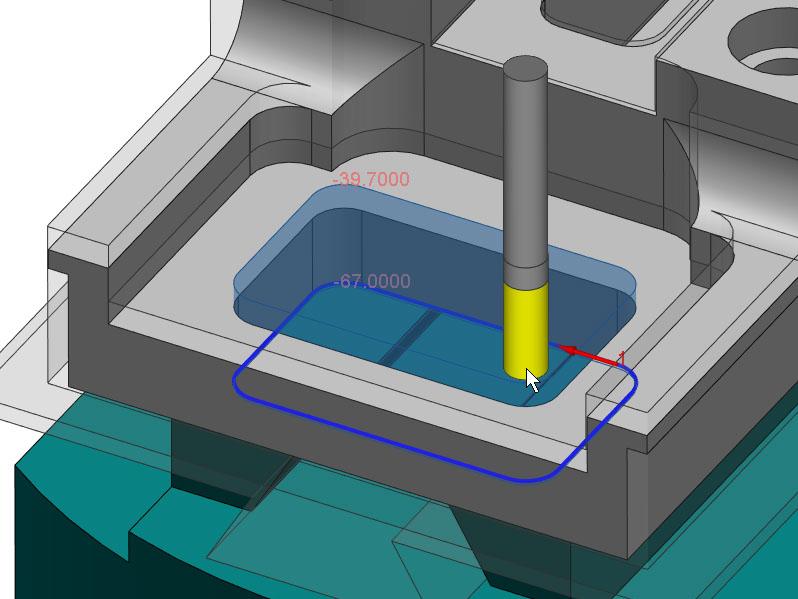

Morphing Spirals

iMachining uses an advanced, patented morphing spiral that gradually conforms to the geometry of the feature being machined rather than an old-fashioned, simple spiral tool path (racetrack). This maximizes tool to stock contact - or - "tool in the cut" time.

Channels and Moats: Divide & Conquer

In order to most efficiently attack large areas of material removal as well as stand-alone islands, they are separated or subdivided into smaller sections using iMachining’s patented Moating technology. This maximizes the continuous morphed spiral cutting.

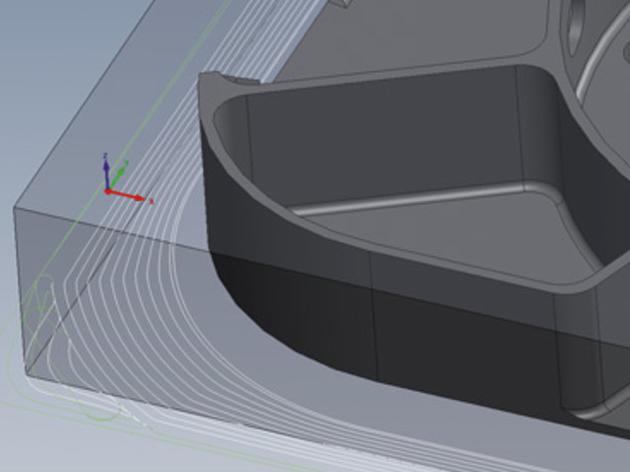

Eliminate Wasted Time & Motion

iMachining tool paths only cut the stock that needs to be removed, eliminating "air cuts". From the initial approach, right to the last cut, rest material tracking ensures every tool path is always cutting.

iMachining 2D with Feature Recognition

iMachining's Feature Recognition technology detects and defines the part machinable features by utilizing the solid model data in combination with minimal input from the user.

Feature Recognition Modes

- Faces: Smart Face technology builds chains by just the simple selection of faces. Entire pocket features and their levels, which can consist of varying depths, are recognized automatically

- Chains: Machinable areas are recognized by chains in combination with the solid model data. Perfect for features not having a floor face to select, such as when milling through pockets and side profiles

- Outside Feature Recognition: Machinable stock surrounding the target is recognized and its levels are detected automatically

- Chains without Feature Recognition: Option to use SolidCAM's standard chaining method without iMachining's Recognition + Protection functionality

Recognition + Protection

Taking into account the Stock/Updated Stock and Target models, iMachining automatically:

- Detects and avoids features that make undercut areas

- Detects and extends stock material in open pocket areas

- Detects rest material at every stage of the machining process

- Protects the solid geometries against cutting tool collisions

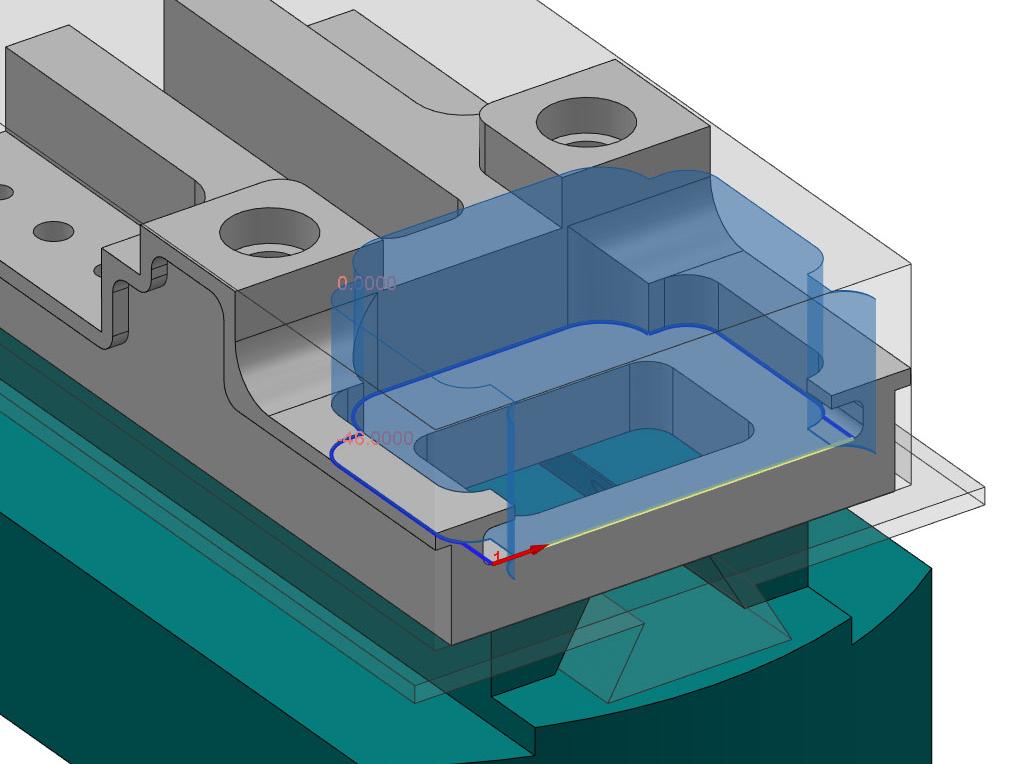

Dynamic Display of Regions

iMachining generates and displays a preview of the machinable regions and their levels. The machining geometry can have varying depths and its preview is dynamically updated on job editing, all of which can be visualized in the SOLIDWORKS Graphics Area.

Trial Download

When compared to any other CAM system to mill a part, SolidCAM's iMachining wins any benchmark in ease-of-use, programming time, cycle time and tool life.

Try iMachining on your part and your machine by downloading our trial version.

English

English German

German Spanish

Spanish Francais

Francais Italiano

Italiano Czech

Czech Japanese

Japanese Dutch

Dutch Turkish

Turkish USA

USA Chinese

Chinese Korean

Korean Russian

Russian Chinese (TW)

Chinese (TW) Vietnamese

Vietnamese